Detect Hidden Pipe Problems: RFT’s Magnetic Power at Work

With Remote Field Testing (RFT), we use powerful magnetic fields to find hidden defects inside steel pipes, even when they’re deep within

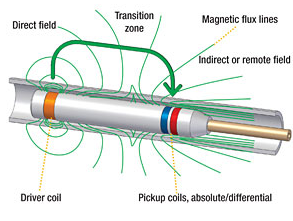

Remote field testing Services (RFT) is an electromagnetic method of testing whose main application is finding defects in steel pipes and tubes. An RFT probe is moved down the inside of a pipe and is able to detect inside and outside defects with approximately equal sensitivity (although it cannot discriminate between the two). Although RFT works in non-ferromagnetic materials such as copper and brass.

RFT probe consists of an exciter coil (also known as a transmitter or send coil) which sends a signal to the detector (or receive coil). The exciter coil is pumped with an AC current and emits a magnetic field. The field travels outwards from the exciter coil, through the pipe wall, and along the pipe. The detector is placed inside the pipe two to three pipe diameters away from the exciter and detects the magnetic field that has travelled back in from the outside of the pipe wall (for a total of two through-wall transits). In areas of metal loss, the field arrives at the detector with a faster travel time (greater phase) and greater signal strength (amplitude) due to the reduced path through the steel.

Remote Field Testing (RFT) is being used to successfully inspect ferromagnetic tubings such as carbon steel or ferrite, or stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts.

Brochure – MS-5800 Brochure

Detect Hidden Pipe Problems: RFT’s Magnetic Power at Work

With Remote Field Testing (RFT), we use powerful magnetic fields to find hidden defects inside steel pipes, even when they’re deep within