Spot Surface Flaws : Penetrant Testing for Perfect Inspections

With Liquid Penetrant Testing, surface cracks and flaws become instantly visible. Our process draws hidden imperfections to the surface.

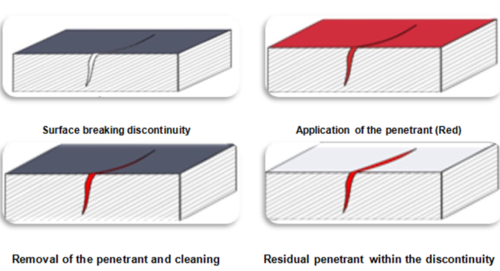

Liquid Penetrant Testing (PT) reveals surface flaws in non-porous material and metallic and non-metallic surfaces by the “bleed-out” of penetrating medium against a contrasting background. This is done by applying a penetrant to the pre-cleaned surface and flaw of the item being inspected.

The penetrant is applied to the surface and allowed to remain on the surface for a prescribed time (dwell time); the penetrant liquid will be drawn into any surface opening by capillary action. Following the removal of the excess penetrant, an application of the developer reverses the capillary action and draws the penetrant from the flaw. The resultant indications reveal the presence of the flaw so that it can be visually inspected and evaluated.

Spot Surface Flaws : Penetrant Testing for Perfect Inspections

With Liquid Penetrant Testing, surface cracks and flaws become instantly visible. Our process draws hidden imperfections to the surface.